Touch Screen Integration

Thoughts before Touchscreen Integration

Before integrating a touch screen you should think about the details of your desired construction. Forward planning will help to guarantee a successful touch integration.

Questions which need to be asked and answered:

- Is enough space for the touch sensor and the flextail (connection cable) available?

- Are the power cable and the flextail not too close to the backlight converter of the TFT panel? (Distance is required)

- Are the ends of the touch-screen not in contact to conducting materials? Avoid contact to metal holders or conducting varnish!

- Maybe the bordering needs to be adapted to pace the touch and the sealing. If the bordering is adapted, has the LCD display been mechanically damaged?

- Is the flex tail cable folded and fixed with enough radius?

- You want to remove the touch-sensor from the TFT display? Please don`t just pull it up instead of following the instructions.

- You want to use solvents? Please follow the provisions and instructions of the manufacturer! Follow as well the instructions of the manufacturer according to usable chemicals for the LCD.

- You want to reassemble the touchscreen sensor to the bordering? Don`t tighten one edge more than the other edges. The tension should be distributed equally over the hole touch.

- Is my device working correctly? Did I assemble everything properly? Run a benchmark test to guarantee the functionality of your touchscreen system.

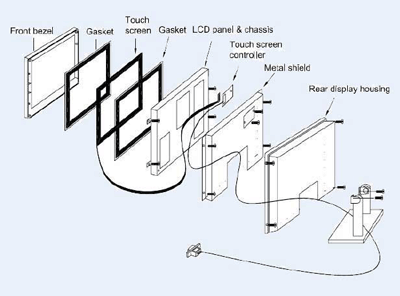

Touch Screen installation in metal housings

Metal can interfere with the touchscreen. That`s why it is very important to be careful with the touch integration in proximity to metal objects. The following instruction will help to successfully install a touch sensor into metal housings.

Avoid contact to the touchscreen with metal items! (No metallic mounting angles, screws or even the metal housing of the LCD panel physically touching the sensor). The touch-sensor may recognize an undesired point of contact.

If your design has a metal bordering please ensure that there`s no contact with the touchscreen-sensor. The bordering should be very solid and professionally grounded. Use isolating tape or a rubber seal as a spacer.

Mention that some plastic borders are coated with conductive lacquer which interferes the same as metal housings. Here the same rules apply as with metal objects!

Positioning of Touch Screens

Think about the optics of your touch sensor. Several light sources outdoor (sunlight) and indoor (incandescent or fluorescent light) can influence the image display of your touchscreen.

Consider different light conditions and changing lights by day as well. Mind the brightness of a place to get a great readability of your touch display.

Maybe you think about using sunlight readable high brightness displays for better outdoor sunlight readability. Observe different sun incidents angles during the year. What is no problem in summer could be in the winter.

Electromagnetic fields can cause problems with electric devices. Radio stations, mobile radio transmitters and deactivaters of safety labels can cause problems with your touchscreen display. This are things you have to plan before the installation of touch-screens.

Touchscreen Cable Routing

To minimise the risk of electromagnetic interference (EMI) never route the touch screen flex tail cable directly next to or over the backlight converter of the TFT panel.

The tail cable is not a grip! Never lift the touch sensor with help of the flex tail. The tail is a electric connection and is not construed for high loads.

The flexible tail has to come out of the side or the top of the LCD display panel. Mind this during the designing of your touch system. Never route the flex tail to come out at the bottom of the display. Interferences and short circuits are the results!

The touchscreen tail is designed to be flexible. The flex tail is foldable one time, in one direction, at one position and then it needs to be fixed with tape.

The tail shouldn`t be moveable after the installation. The hole edge of the touch sensor should be fixed with glue!

Summary:

Onetouch-touch screens are mountable on most TFT displays. Every LCD TFT panel has special things which need to be considered during the integration. But there are general steps for the installation of every display panel:

- testing the video-output of the TFT display

- removing the TFT LCD panel (if necessary)

- mounting the touch sensor to the front of the LCD display

- install the touch controller (intern or extern)

- assemble TFT panel

-

connect LCD display panel and touch-screen sensor to computer system

Mounting the touch sensor to the TFT panel

Most important: test the functionality of your display before mounting it!

It`s irrelevant if you want to install the touchscreen-sensor to a new or an old display, it is absolutely necessary to check the TFT LCD panel and the VGA-output. You can compare the result before and after the installation.

If the TFT display works correctly switch of the system and disconnect the connectors and cables from the panel. Now you are ready to remove the displays and mount the touch-screen-sensor.

Installation of your Touchscreen System

A slim stripe of double-sided foam-tape should be used to fix the touch sensor on the metal frame of the TFT panel. The touchscreen sensor needs to be mounted with a constant distance between sensor and LCD display. The distance should not vary under compression, different contact pressures or temperature fluctuations.

The hole edge of the touchscreen should be fixed and the tape 1-2mm thick. Don´t leave any room for gaps. The tape prevents the space between touch-sensor and TFT panel from dust and dirt. The tape fixes the sensor within its place.

We recommend the usage of non-acidic, pH-neutral tape.

Make sure the tape is not visible after assembling the LCD display panel.

Please be aware that some sealing materials contain chemicals (sulphur, acidic materials or chlorine) which can influence the functionality of your touchscreen. Before selecting sealing materials, it`s important to know the ingredients and chemical compounds. It´s important to keep touchscreens away from chemically acting and acidic materials.

Mistakes like that during touchscreen installation can cause reduced precision and temperature range.

Touch Screen Sensor Positioning

The precise positioning of the touch sensor is extreme important. A bit of exercise is needed to place the sensor on the vertical and horizontal axis of the TFT display panel. The touchscreen-sensor needs to be exactly aligned with the LCD panel.

- Place the display with the front to the top on a foam mat and be careful with the components on the back of the panel.

- Pay attention with the correct positioning of the flex tail cable. If you are not sure which position is the right one please contact us or look at the technical instructions/drawings of your sensor. The tail is only bendable in one direction and at one point.

- The last step is the precise positioning of the touchscreen on the LCD panel. Make sure the sensor is straight and central on the visual surface of the TFT LCD display.

Care and Cleaning

- Avoid acidic chemicals and vinegar-based cleaners

- Moisten a cloth with cleaner and clean the display. Never directly spray the cleaner on the panel.

Touchscreen Mounting

- As soon as you are satisfied with centration and positioning of the touch-sensor, you are ready to permanently install the senor to the LCD panel.

- Use the recommended cleaner and a soft, lint-free cloth to clean the touch screen.

- Attach a strip of double-sided foam tape around the edge of the TFT panel.

- Place the touch-sensor with the flexible tail in the right position.

- Mount the sensor in a smooth motion to the display. If available use your registration marks for correct positioning.

Checking the glued Touchscreen

- Place the LCD panel in an upright position.

- Look at the front of the TFT display and make sure the flexible tail is correctly positioned.

- Proof the centration. If the touchscreen is not centred you have to remove it and place it again.

- Check if there are any inclusions like dust and dirt between TFT LCD panel and touchscreen sensor.

Removing the Touchscreen

If you want to remove the touch sensor don`t try to pull it up from the TFT LCD display panel! The glass could break and injure you and others!

- Use a fishing line, steel wire or a razor blade to cut the tape carefully. Start at the top of the panel and then move upwards at the sides. Be careful! Don´t scratch the TFT panel or even the touch sensor. Hold the touchscreen when the display comes off.

- Use isopropyl alcohol to remove residues of the tape from the back of the touchscreen-sensor. If you use solvents follow the instructions of the manufacturer. Follow as well the instructions of the manufacturer according to the usage of chemicals for the LCD display panel.

- Repeat the procedure of mounting the touchscreen sensor to the LCD TFT display.

Mounting of Touch Controllers

Serial Controller:

The RS232 controller needs an internal power supply by the TFT LCD display. The controller needs to be mounted internally.

USB Controller:

USB-Controllers need a connection to the USB ports of the computers. They don`t need internal or external power. The controllers work as soon as they are connected to the USB-port of the computer.

We are looking forward to your inquiry!

Thank you for your inquiry. We want to answer quickly and accurately and need following information:

- Article, product description, application

- Number of pieces

Only with this information we can answer quickly and qualified to make you an offer. Thank you very much!

Please note that we only supply to:

- Commercial customers

Contact distronik GmbH:

82024 Taufkirchen bei München, Bergstr. 12

Tel. +49-(0)89-623 036 394 - Fax: +49 (0)89 623 036 398