4- and 5-wire resistive Touch Screens for industrial Usage

Functioning of resistive touchscreen panels

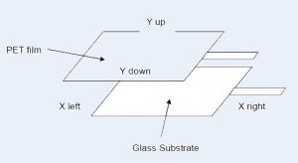

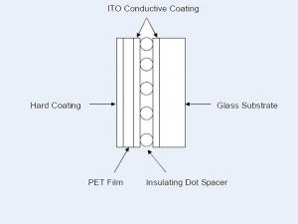

The basis of a resistive touch is the glass carrier material, coated with a resistive layer (ITO).

An ITO coated polyester top layer is spanned over the glass surface of the resistive touchscreen. But these two layers are separated by invisible spacers.

If the sensor is touched, an electrical connection between the glass and the foil arises.

The touch controller board evaluates the resistance value.

- Easy integration of Touchscreen module

- Easy handling, in metal housings as well

- Sealable, IP65 possible

- Easy to operate with pencil or gloves (medical technology)

- Solid surface (3H)

- Great compatibility with detergents, acids, etc.

- Excellent price/performance ratio

Advantages of industrial resistive Touchscreens

The resistive touch technology is ideal for the industry. The only disadvantage is the light transmission but the advantages outweigh:

Resistive 5-wire

- ~80% light transmission

- great linearity, for large screen sizes

- Life time ~35 million touch cycles

Resistive 4-wire

- ~ 80% light transmission

- moderate linearity, better for smaller screen sizes

- Life time ~ 1 million touch cycles

We are looking forward to your inquiry!

Thank you for your inquiry. We want to answer quickly and accurately and need following information:

- Article, product description, application

- Number of pieces

Only with this information we can answer quickly and qualified to make you an offer. Thank you very much!

Please note that we only supply to:

- Commercial customers

Contact distronik GmbH:

82024 Taufkirchen bei München, Bergstr. 12

Tel. +49-(0)89-623 036 394 - Fax: +49 (0)89 623 036 398